Top Guidelines Of gearbox cvt

Top Guidelines Of gearbox cvt

Blog Article

CVTs are less complicated and much more adaptable than common transmissions, presenting outstanding gas economic system and seamless efficiency via different driving ailments. However, some motorists do not like the way in which they feel or seem, and they are often costly to mend or substitute.

Fuel efficiency and decreased emissions are the very best great things about repeatedly variable transmissions. The CVT’s capability to keep up exceptional motor rpm and car momentum by way of its shiftless operation produces a more efficient program than classic automatic and guide transmissions. Remaining nearer for the the best possible rpm assortment also spots less strain around the automobile’s engine.

Considering that the CVT isn’t shifting gears, the ride is smoother, which several may possibly prefer to the somewhat jerky feeling of the automated transmission.

벨트 장력을 유지하기 위해 유압을 따로 적용하며 이로 인해 효율성이 떨어진다. 엔진의 최적 회전수 영역에서는 무단변속이 이 단점을 상쇄하지만, 최고 단수 영역에서 엔진의 회전수가 계속 올라가는 경우 자동변속기 대비 효율이 떨어진다.

CVT transmissions function to the basic principle of protecting the engine at its optimal speed, called the "electricity band," for max performance. This is a simplified clarification of their operation:

You puuuulllll pull the toy backwards along with the motor tightens…..which means you pull it again…hold it…and “Allow it Go!”

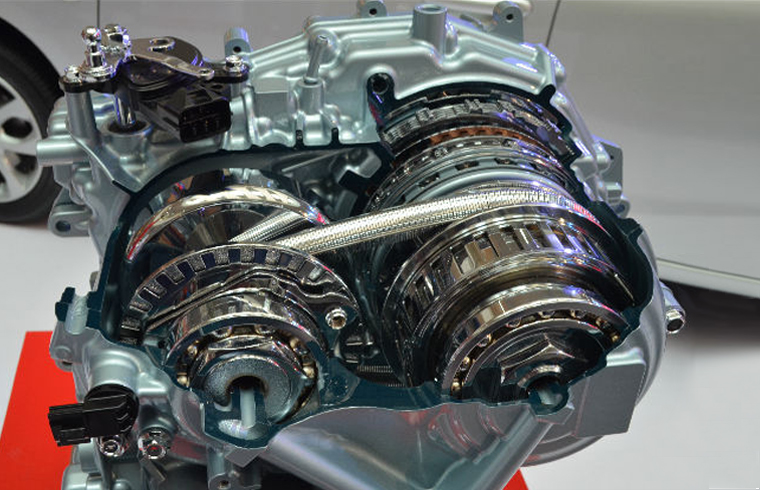

This type of CVT uses a process of pulleys and belts or chains to fluctuate the gear ratio consistently. Since the car accelerates, the pulleys regulate their diameters to keep up optimum motor pace, resulting in seamless acceleration without the need of discrete equipment shifts.

Though CVTs have many Positive aspects, they even have some possible disadvantages. Such as, some drivers could notice that the lack of distinct equipment shifts will make it tricky to choose how the vehicle is undertaking, and Other people might find the engine sounds to generally be extra visible than with a conventional transmission.

A further downside of CVTs is that they is often noisy once the motor is under significant load. It is because the transmission is consistently modifying the pulleys and belt to maintain the motor in its optimal electricity array, which may lead to a whining or droning sound. While some motorists may well not mind the noise, Other individuals may possibly uncover it distracting or aggravating.

Nissan then switched from toroidal to pulley-centered CVTs in 2003.[43] The Variation in the CVT made use of Using the VQ35DE motor in the fourth-era Nissan Altima is claimed to generally be capable of transmitting better torque hundreds than other belt CVTs.[44]

This 2nd sort of design is analogous in theory to a pulley-centered CVT but nevertheless a bit distinct. The components associated Here's electricity rollers and discs, rather than pulleys and belts. There's two disks involved with two rollers between.

The most typical form of CVT employs a V-belt which runs among two variable-diameter pulleys.[1] The pulleys consist of two cone-formed halves that shift together and aside. The V-belt operates amongst these two halves, Therefore the effective diameter of the pulley is depending on the gap amongst the two halves of the pulley.

A repeatedly variable transmission (CVT) is an automatic transmission that can modify by way of a ongoing number of equipment ratios. This contrasts with other transmissions that provide a restricted variety of equipment ratios in preset steps.

Comme le changement de diamètre d'une poulie est toujours progressif, on parle de variation carry on. Il n'y a pas de saut entre chaque order sekarang rapport comme c'est le cas sur une boîte de vitesses traditionnelle.